The mechanical, electrical, and software components described on the Sim Two pages are just the beginning of the overall motion sim system development. Once each of the components has been built and installed on the lower platform, the next step is testing of the mechanical components to determine whether they move as designed when power is turned on. After that there is software configuration and testing to make sure that a user enjoys the experience, feels that the flight experience is realistic, and stays safe while the platform moves in response to their control of the simulated aircraft.

This section contains observations made during our system configuration and testing. Note that there are dozens of specific software settings (i.e., variables) that can be applied to the Kangaroo motor controllers, the BFF motion control software, and the simulator program itself (MSFS 2020 in our case) that can affect the overall user experience. And within the range of settings that can be considered safe — meaning the platform does not damage itself with violent movements of the actuators — there is quite a large range of speed limits that can be applied to platform motion to make it behave like a docile flight trainer, a competition aerobatic plane, all the way up to a mechanical bull able to toss the rider (and computer components!) into the air.

Mechanical modifications

Originally we chose to bolt the actuator pushrods directly to the swiveling rod-end bearings mounted on the upper platform. We found that this arrangement transmitted too many sharp pulses to the platform, even when the actuators were being commanded to simply hold the platform in position. This occurred because the Kangaroos send a positioning command to the actuators and then monitor the feedback potentiometers to determine whether that position is being held correctly. With the weight of a rider on board, the platform tends to sag slowly, causing the Kangaroos to send an additional repositioning ‘pulse’ to restore the desired position.

These small but sharp pulses were smoothed out by adding “die springs” above and below the actuator linkages to the upper platform:

The springs are preloaded by squeezing them about 1/4 inch with nuts and washers. They do not move very much but the improved ride of the upper platform is quite noticeable.

Software components

As outlined in the BFF Motion Control Software User Guide, the first step of software configuration is to use the DEScribe software to do a ‘limit switch tune’ of the Kangaroos and their associated motor controllers and actuator. The tuning procedure will program the Kangaroos with the actually observed voltages (between 0 and 5 volts) recorded from the position sensing potentiometers. The tuning will also establish the voltages associated with the actuators reaching the upper and lower limit switches, and create ‘soft limits’ that represent 85% of the total actuator movement observed between the limit switches. This is all automatic if the components have been installed and wired correctly.

One automatic setting that we found had to be changed was the maximum speed of movement of the actuators. The DEScribe software sets this value as maximum “lines” per second (where a line is just a millivolt), and the default is to just record the maximum total observed potentiometer voltage change from lowest actuator position to highest position as the maximum speed per second. We found this is too fast, and can cause very uncomfortably rapid up and down oscillations of the platform. We used the DEScribe software to manually enter a maximum speed value about 50-60% of the value created by DEScribe, and saved that in the Kangaroo configuration record (which is then uploaded to the Kangaroo firmware after changes are made). This reduced maximum speed made for smoother, but still responsive flying.

After the Kangaroos and their associated actuators have been tuned, the BFF motion control software then also needs to be tuned to respond appropriately to the flight physics engine data that is delivered from MSFS via the FSUIPC7 software program. There are many variables that affect Pitch, Roll and Heave responses and these are all contained in an ASCII text file that has a .BFF file name extension (and generally has the word Kangaroo in the file name.) A sample Kangaroo.BFF file is included with the BFF software download, but we found it needed many changes to be usable for our platform configuration. Particularly, the default file has actuators set up in Mode 1 (3DOF), which you would think is correct. However, after many hours of trial and error we discovered the correct mode for one Kangaroo controlling the two actuators in the rear and a separate Kangaroo controlling the pitch actuator in the front is actually Mode 2, with the front actuator set for reverse sensing(!). We also learned that it will probably be necessary to create aircraft-specific BFF configuration files, since the platform responsiveness and limits of travel may differ quite a bit for a docile trainer like a Cessna 172 compared to a competition aerobatic aircraft like the Extra 300 included in MSFS.

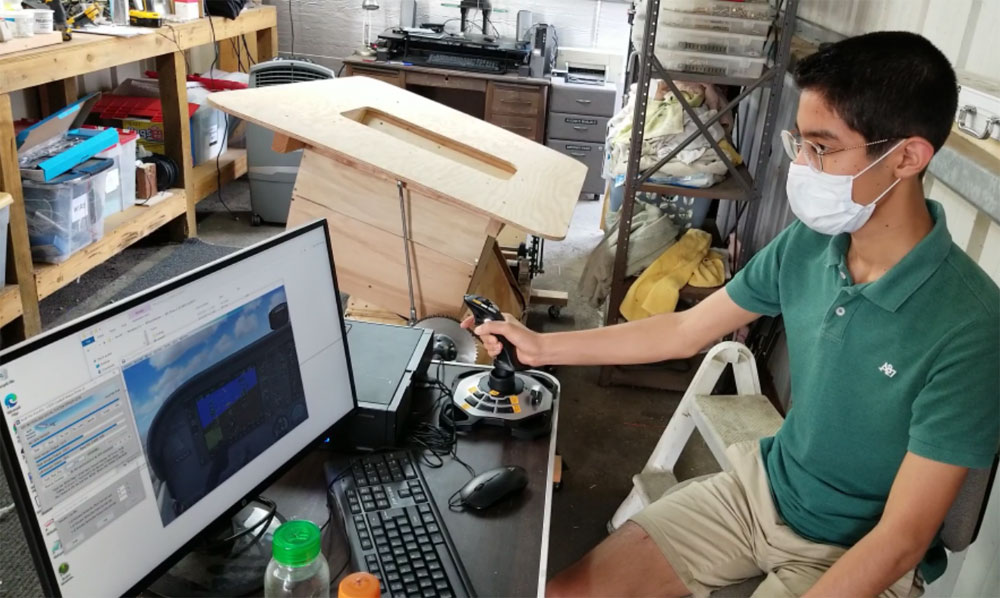

If you want to learn more, contact us and we will be happy to help with more detail on Kangaroo and BFF motion program configuration information representing our best guess at the time! We continue to learn how different individuals, young and old, some pilots and some not, interact with the systems. For example, older pilots seem prone to overcontrolling the sim using the Logitech joystick, but youngsters with gaming experience have no trouble with it. For this reason we added the option of using a Logitech Yoke and Throttle quadrant that more closely emulates the yoke found in Cessnas, Pipers and other common general aviation aircraft. Even with a motion sim that has met all of our goals and visions for how it should work, our journey of learning continues!

Our “Lessons Learned” from FlightSim Two helped inform our design of FlightSim Three, and on that page we discuss some of the limitations of the FlightSim Two design that led us to go back to a simpler design for our most recent flight simulator.

Last update May 23, 2023